Leading the middle-end packaging equipment industry

How to maintain and maintain the heat shrink packaging machine?

Sep 19,2022

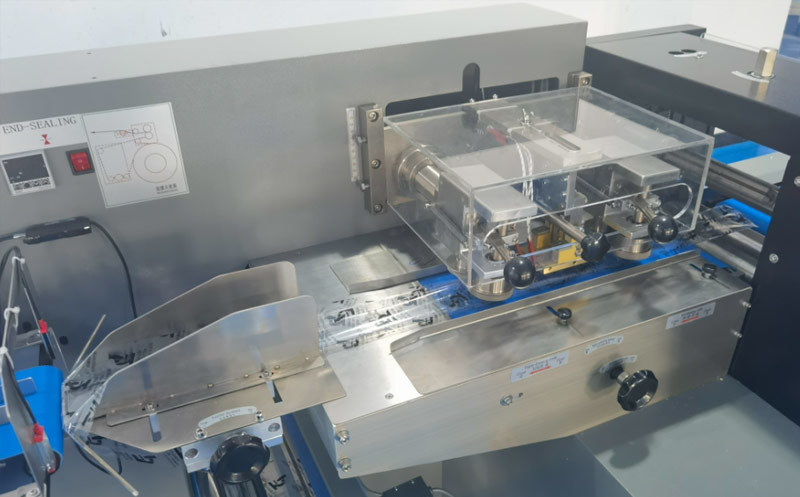

As a common equipment in the production industry, the hot regenerator has been widely used in food, beverage, daily necessities and other industries. In order for the heat regenerator to work smoothly, daily maintenance is also essential. Lubrication during use is also very important, so how to maintain and maintain the heat shrink packaging machine?

1. Vacuum packaging machine regularly replace the vacuum pump oil, the joint regularly refueling. Thermal lubrication is also essential.

2. The operation of the hot roll closure requires every part of the equipment, regular cleaning of the parts, and daily basic maintenance. Lubrication is a prerequisite for equipment operation. Therefore, when lubricating the parts of PE film, pay attention to the working function of the equipment.

3. Thermal rewriting is a commonly used device that requires regular lubrication of the meshing part of each gear, the oil injection hole and the moving parts of the seat bearing. Although it works a few days per shift, the thermal enhanced belt is a device that is prone to wear and tear on the job. When refueling the heater, please be careful not to drip oil on the heat shrink belt to avoid slipping or premature wear of the belt.

4. In the hot processing part, the reducer is an important part of the equipment. It is strictly prohibited to run without oil, after 300 hours of operation, clean the interior and change the oil, and then replace it every 2500 hours. Therefore, although hot repair is high-tech equipment, it is still necessary to pay attention to operation in the work. There are many precautions for lubrication of all components.

5. Therefore, the precautions for operating the hot rewriter are a prerequisite for equipment maintenance and normal operation.

What is the maintenance method of thermal reduction of heat shrink packaging machine?

1. Please keep the temperature at -10-50, the relative humidity is less than 85%, and there is no corrosive gas, dust or explosion danger in the air.

2. In order to ensure the normal operation of the vacuum pump of the thermal rewriter, the vacuum pump motor is not allowed to reverse. Check the oil level frequently. The normal oil level is 1/2-3/4 of the oil window (no more). When the vacuum pump turns dark or the color of the oil turns black, replace the new oil in time.

3. The Inca filter should be carefully removed and cleaned.

4 Open the back cover for 2-3 months, add the folded part, switch the addition of lubricating oil, and adjust the lubricant of the hot rod connection part.

5. Regularly check the three connections of decompression, filtration and oil mist 24 to ensure that there is oil in the oil mist and oil cup (sewing machine oil), and there is no water in the filter cup. Keep the tropical and silicone tape clean, do not attach foreign matter, do not affect the sealing quality.

6 On the hot patch, the double layer of skin cream under the heating sheet acts as insulation. If damaged, replace in time to avoid short circuit.

7. Regularly lubricate the gear meshing parts, bearing oil injection holes and moving parts. Oil-free operation is strictly prohibited. After 300 hours of operation, clean the interior and replace with new oil, then change the oil every 2,500 hours.

Hot Tags:

Contact Us

E-mail:

Phone/Wechat:

Address:

Dong ma juan industrial park, wuqing district, tianjin city 301717

Related Posts